Gallery

Technical

.png)

%20(1).png)

Heading

Personal

Bachelor of Science in Mechanical Engineering -

December 2016

The University of Alabama

Website -

SamuelHager.webflow.io

Home Town -

Boulder, Colorado

Hobbies -

3D printing/Design, Hiking, Skiing, Running/Fitness, Skateboarding, Biking, Video Games, Cooking

Hello! My name is Samuel Hager, and I am the Head of US Engineering for PERI 3D Construction. Three years ago, I was hired to kick off the US division of PERI 3D Construction. In that time, I have worked directly on over six separate 3D printed structures in the US and Europe. In 2020, I was honored to work alongside Habitat for Humanity as the project lead on their first ever 3D printed structure. In July of 2020, we printed the last layers of the Habitat home in Tempe, AZ, and this home became the first 3D-printed home in the US to be sold with a mortgage to a real family. More recently, I have begun printing the first layers of the first 2-story 3D printed structure in the US. This home, named "The Collectors House," will be a luxury custom 3D home designed to take full advantage of the capabilities of 3D construction. Every wall has been painstakingly designed to highlight the architectural freedoms that 3D construction grants home builders and architects. Our first media event will be held on 9/12/22, be sure to save the date!

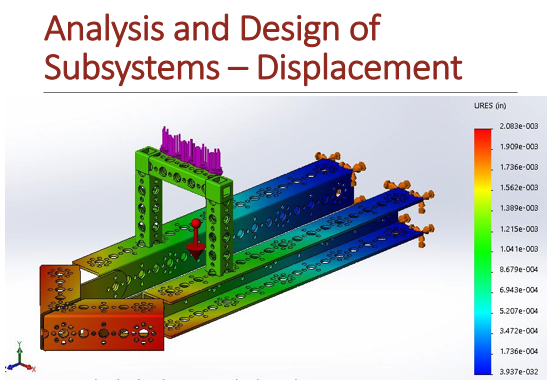

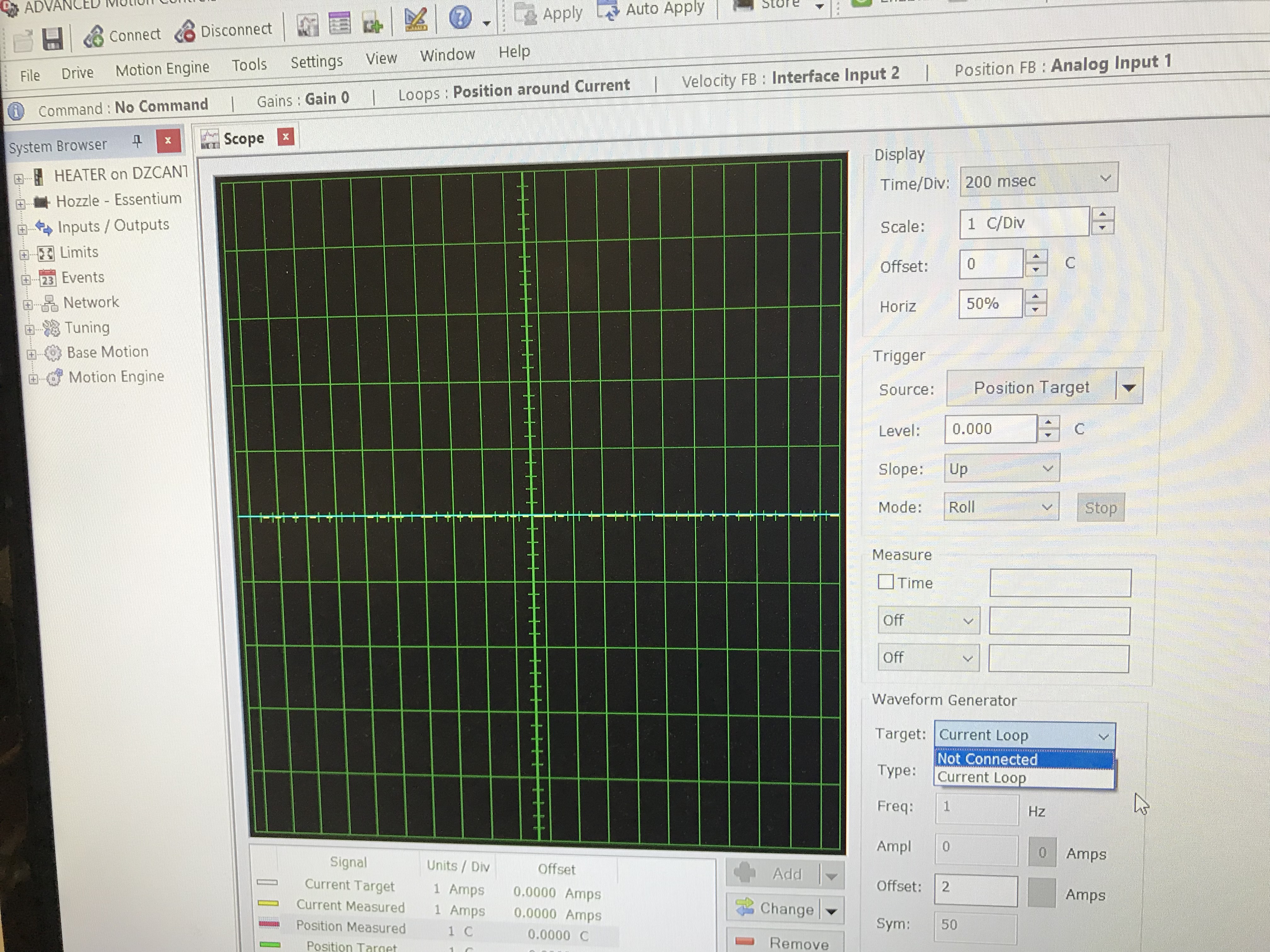

Before working at PERI, I earned my degree from The University of Alabama. After graduation, I worked for three years as a research and development engineer at Essentium Inc., a growing 3D printing start-up based out of Austin, Texas. Working in R&D, technical sales, and later business development for polymer 3D printing technology proved to be an amazing opportunity to learn to adapt quickly and problem solve while continuing to grow my interest in pursuing a career in engineering and business development. I was grateful to represent Essentium at international trade shows, including FormNext and Rapid. Additionally, I worked alongside clients like NASA's Johnson Space Center, the US Airforce, Reebok, BASF, and several other Fortune 500 companies. Seeing my research materialize into real-world benefits for a wide variety of manufacturing clients and partners solidified my commitment to continue a career in additive manufacturing.

.png)

%20(1).png)